Basic features

FOR DIFFERENT AMBIENT CONDITIONS

– operation for 8 hours per day

– operable in dust and moisture ambient

STANDARDY

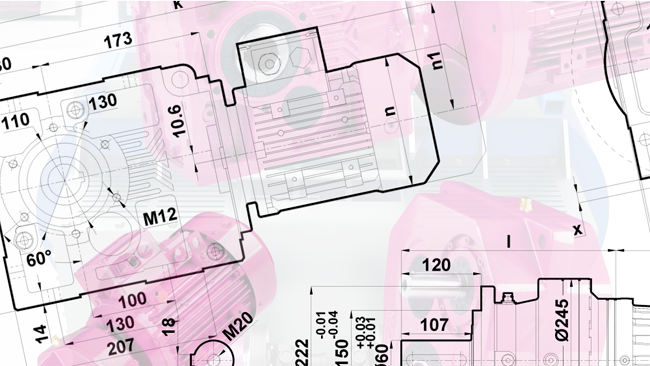

– construction and properties according to ISO 281, ISO 6336 and DIN 743

SAFETY

– emphasis on bearing life

– testing and stress analysis of the gearbox housing

VALUE ADDED

– minimum torque for all configurations

– long life

1. monoblock construction

The unique design guarantees low noise, reduced oil leakage and higher strength and accuracy on the entire gearbox.

2. processing accuracy

All axes are machined on the same mounting plate, ensuring high accuracy on the entire gearbox.

3. longer life

Monoblock construction allows for greater load and also guarantees a longer bearing life as well as the gearbox itself.

4. gearbox cast plate

The gearbox plate is integrally cast and provides optimum support for bearings used in three-speed gearboxes.

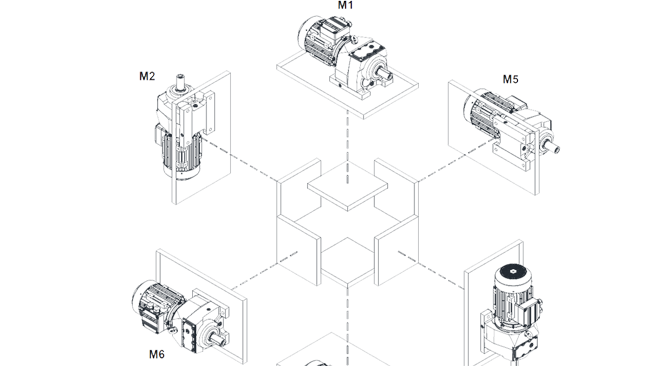

5. two- or three- stage

All gearbox models are two- or three-stage and the foot or flange model can be selected.

Wide configuration options

1. state-of-the-art procedures

Gearing, bearing life, shaft strength, etc. are calculated by professional software applications according to DIN and Niemann guidelines.

2. low axle height

New gearboxes have lower axle heights than old models. At the same time, they are more compact at the same power and speed.

3. modular design

All gearboxes have a modular design, so they can be integrated with other products on the market with minimal effort.

4. other options

The new generation of Yilmaz Redüktör gearboxes enables a wide range of wiring and mounting options.

Gearbox efficiency

worm

50 – 90 %

bevel

helical